Geschenke für 2-jährige Mädchen

Was kann man 2-jährigen Mädchen schenken? Womit spielen Kinder, die gerade die Welt für sich entdecken? Hier findest du kleine Geschenke und sinnvolle Spielsachen, die zum Entwicklungsstand von 2-Jährigen passen. Endecke Geburtstagsgeschenke, Weihnachtsgeschenke und Ostergeschenke, die zweijährige Mädchen in ihrer motorischen und geistigen Entwicklung fördern.

Bewährte Spielsachen und sinnvolle Geschenke für Mädchen zum 2. Geburtstag

Mit 2 Jahren sind Mädchen noch nicht auf bestimmte Spielsachen geprägt. Die Auswahl von Spielzeugen liegt noch weitestgehend in der Hand der Eltern, die vor der Herausforderung stehen, geeignete Geburtstagsgeschenke und Weihnachtsgeschenke für die Tochter zu finden. Das Wachstum der Kinder schreitet schnell voran und bald ist auch schon der 2. Geburtstag der Tochter. Im Kinderzimmer von 2-Jährigen findet man viel Lernspielzeug und Motorikspielzeug, weil Eltern besonders in dieser wichtigen Lebensphase Einfluss auf die positive Entwicklung der sprachlichen und motorischen Fähigkeiten ihrer Tochter nehmen können. Empfehlenswert sind in diesem Alter zum Bespiele Zuordnungsspiele für Farben und Formen, die den Kindern einfache Regeln und Spielabläufe näher bringen. Bei der Zusammenstellung von sinnvollen Geschenken für 2-jährige Mädchen haben wir darauf geachtet, den Fokus auf pädagogisch wertvolle Spielsachen zu legen.

Checkliste: Spielsachen und Geschenke für Mädchen im Alter von 2 Jahren

- Die geistigen und motorischen Fähigkeiten machen bei 2-jährigen Mädchen rasante Fortschritte. Die Kinder können bereits Farben und Formen richtig zuordnen und sind in der Lage, einfache Regeln und Spielabläufe zu verstehen. In diesem Alter sind Zuordnungsspiele mit Farben und Formen geeignet, um die Kleinen sinnvoll zu beschäftigen.

- Die Sprache macht ebenfalls eine rasante Entwicklung. Zweijährige benutzen bereits Wörter im richtigen Zusammenhang und lernen neue Bezeichnungen dazu. An der klaren und verständlichen Aussprache gibt es jedoch noch viel zu verbessern. Auf spielerische Art zu Weise fordern Lerncomputer die Kinder zum Nachsprechen auf, und vermitteln mit schönen Kinderliedern und spannenden Geschichten die richtige Aussprache der Wörter.

- Kleinkinder werfen Spielzeug, lassen es fallen oder kauen darauf herum. Robustes Spielzeug, dass frei von jeglichen Schadstoffen ist, eignet sich am besten als Geschenk für 2-jährige Mädchen. Zudem sollten die Spielsachen nicht aus Kleinteilen bestehen, die die Kinder verschlucken könnten.

Was kann man einem 2-jährigen Mädchen schenken?

Im Alter von 2 Jahren haben Mädchen nur eine kleine Aufmerksamkeitsspanne. Neues Spielzeug muss einfach zu handhaben sein und darf die Kleinen nicht überfordern. 2-jährige Kinder können Farben und Formen zuordnen und Spielsteine mit großen Flächen ausbalancieren. Auch das Kritzeln auf Malvorlagen macht ihnen viel Spaß. Sinnvolle Geschenke für 2-jährige Mädchen sind also Spielsachen, die leichte Herausforderungen an die geistigen und motorischen Fähigkeiten stellen.

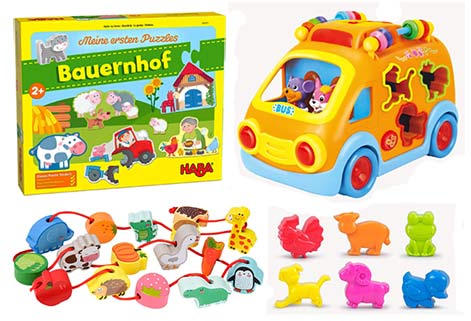

1. Zuordnungsspiele

2-jährige Mädchen können schon Abbildungen und Gegenstände nach einfachen Merkmalen zuordnen. Sinnvolle Geschenke zum 2. Geburtstag sind zum Beispiel Memorys oder Spiele, bei denen es darum geht, gängige Tierarten oder Obstsorten zu benennen und zu sortieren. Wenn die Kleinen sich schwertun, können die Eltern weiterhelfen. Das gemeinsame Spielen stärkt die Eltern-Kind-Beziehung und die Erwachsenen erfahren etwas über den geistigen und motorischen Entwicklungsstand ihrer Tochter.

2. Malbücher

Ab dem zweiten Lebensjahr unternehmen Kinder ihre ersten Malversuche und entwickeln viel Freude am bunten Ausmalen. Mit Malbüchern lernen die Kleinen etwas über Tiere und Gegenstände des Alltags und verbessern beim Malen ihre Hand-Auge-Koordination. Begeistern kann man Zweijährige auch mit Malbüchern zu ihren Helden aus den Zeichentrickfilmen. Die Kinder können beim Ausmalen kreativ werden und sind über viele Stunden sinnvoll beschäftigt.

3. Holzbauklötze

Farbige Holzbausteine sind auch für Mädchen ein hervorragendes Spielzeug zur Verbesserung der Geschicklichkeit. Beim Stapeln müssen die Zweijährigen die Bauklötze ausbalancieren, damit die Konstruktion nicht umfällt. Geduld und eine ruhige Hand sind bei dieser Herausforderung besonders wichtig. Holzbauklötze sind schon lange ein bewährtes Motorikspielzeug und in jedem Kindergarten finden.

4. Sandspielzeug

Auf dem Spielplatz oder am Strand spielen 2-Jährige gerne im Sand. Türme bauen, Backwaren zubereiten oder Eis verkaufen – Sand bietet kleinen Mädchen viel Raum für Fantasie und Kreativität. Mit Eimer, Schaufel und Sandförmchen können sich die Kleinen stundenlang beschäftigen und viele Eindrücke aus er Erwachsenen-Welt nachspielen. Als Alternative zum Sandkasten empfiehlt sich für zuhause ein Sandspieltisch oder eine Sandmuschel. Beides kann man auf dem eigenen Grundstück oder auf dem heimischen Balkon aufbauen und mit Sand befüllen. So sind die Kinder sinvoll beschäftigt, und die Eltern können das warme Wetter und die Sonne genießen.

Soll ich meiner 2-jährigen Tochter Lernspielzeug schenken?

Um die Tochter auf die bevorstehende Zeit im Kindergarten vorzubereiten, ist es durchaus sinnvoll, einem Mädchen schon im Kleinkindalter Lernspielzeug zu schenken. Achte allerdings darauf, dass das Spielzeug nicht nur zum Lernen da ist, sondern dem Kind auch Spaß beim Spielen bringt. Am einfachsten erzielt man bei 2-jährigen Kindern Lerneffekte auf spielerische Art und Weise, also wenn die Tochter nicht das Gefühl hat, gerade etwas zu lernen. Dazu sollte das Lernspielzeug einen gewissen Unterhaltungswert haben.

- Das beste Lernspielzeug für Kinder ab 2 Jahren

- Das beste Motorikspielzeug für Kinder ab 2 Jahren

- Kleine Geschenke für Kinder unter 5 Euro

- Kleine Geschenke für Kinder unter 10 Euro

- Geschenke für 1-jährige Jungs

- Geschenke für 2-jährige Jungs

- Geschenke für 3-jährige Jungs

- Geschenke für 4-jährige Jungs

- Geschenke für 5-jährige Jungs

- Geschenke für 6-jährige Jungs

- Geschenke für 1-jährige Mädchen

- Geschenke für 3-jährige Mädchen

- Geschenke für 4-jährige Mädchen

- Geschenke für 5-jährige Mädchen

- Geschenke für 6-jährige Mädchen

- Geschenke für 1-jährige Kinder

- Geschenke für 2-jährige Kinder

- Geschenke für 3-jährige Kinder

- Geschenke für 4-jährige Kinder

- Geschenke für 5-jährige Kinder

- Geschenke für 6-jährige Kinder

- Balkonspielzeug: 5 tolle Balkon-Spielsachen für Kinder

- Die 34 beliebtesten Spielzeuge für 2-jährige Kinder

- Die 41 beliebtesten Spielzeuge für 3-jährige Kinder

- Gartenspielzeug: 50 tolle Outdoor-Spielzeuge für Kinder